Getting Started

Cognex® VisionPro® ViDi software provides a collection of machine vision tools which tackle different hard to program challenges through the use of deep learning.

Deep learning technology uses neural networks which mimic human intelligence to distinguish anomalies, parts, and characters while tolerating natural variations in complex patterns. Deep learning offers an advantage over traditional machine vision approaches, which struggle to appreciate variability and deviation between very visually similar parts.

Deep learning-based software optimized for factory automation can perform the following:

- Solve vision applications too difficult to program with rules-based algorithms

- Handle confusing backgrounds and poor image quality

- Maintain applications and re-train on the factory floor

- Adapt to new examples without re-programming core algorithms

- Be used by non-vision experts

In factory automation, deep learning-based software like VisionPro ViDi can now can perform judgment-based part location, inspection, classification, and character recognition challenges more effectively than humans or traditional machine vision solutions.

Unlike machine vision systems, which operate via step-by-step filtering and rule-based algorithms, deep learning-based image analysis software learns by example—as a human would—from a set of annotated training data and images which represent a part’s known features, anomalies, and classes. During training, the software develops neural networks that can model a part’s normal appearance and defects. During run-time, the software locates parts, extracts anomalies, classifies parts, and even deciphers hard-to-read characters with speed, robustness, and precision.

This novel approach, which tolerates deviation and unpredictable defects, beats even the best quality inspectors, and is ideal for the following applications:

- Defect detection

- Texture and material classification

- Assembly verification and deformed part location

- Character reading, including distorted print

VisionPro ViDi combines the specificity and flexibility of human visual inspection with the reliability, repeatability, and power of a computerized system – all in an easy-to-deploy interface.

|

|

|

|

|---|---|---|

|

More consistent – Operates 24 x 7 and maintains the same level of quality on every line, every shift and every factory. |

Designed for hard-to-solve applications – Solves complex inspection, classification and location applications impossible or difficult with classic rules-based algorithms. |

Requires less data and computing power – Training requires hundreds of images instead of millions. Since images are stored locally and require minimal computing resources deployment is fast and affordable. |

|

More reliable – Identifies every defect outside of the set tolerance. |

Easier to configure – Applications can be set up quickly, speeding up proof of concept and development. |

Simple training interface – Software is designed for real-world factory conditions, with no special expertise required. |

|

Faster – Identifies defects in milliseconds, supporting high-speed applications and improving throughput. |

Tolerates variations – Handles defect variations for applications that require an appreciation of acceptable deviations from the control. |

Global support – Cognex’s network of engineers and technical experts provide world-class application support. |

Cognex ViDi deep learning-based algorithms are optimized for real-world industrial image analysis, requiring vastly smaller image sets and shorter training and validation periods. Choose between Red Analyze, Green Classify, Blue Locate, and Blue Read tools to solve your highly supervised to completely unsupervised applications.

|

Locates features |

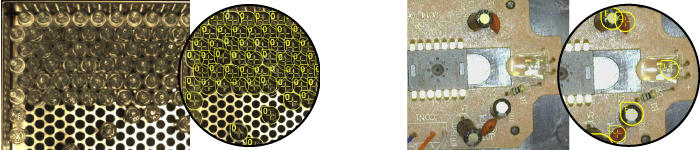

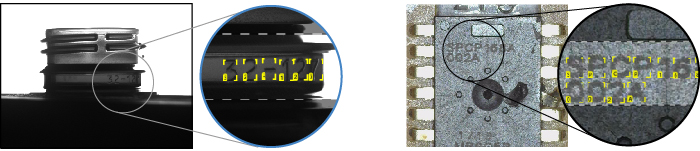

The ViDi Blue Locate tool finds complex features and objects by learning from annotated images. Self-learning algorithms locate parts, count translucent glass medical vials on a tray, and perform quality control checks on kits and packages.

|

|

Detects anomalies and aesthetic defects |

The ViDi Red Analyze tool segments defects or other regions of interest simply by learning the varying appearance of the targeted zone. The tool identifies scratches on complex surfaces, incomplete or improper assemblies, and even weaving problems on textiles simply by learning the normal appearance of an object including its significant but tolerable variations.

|

|

Classifies objects or scenes |

The ViDi Green Classify separates different classes based on a collection of labeled images. By training on acceptable tolerances, the tool identifies products based on their packaging, classifies the quality of welding seams and separates acceptable or unacceptable anomalies.

|

|

Reads text and characters |

The ViDi Blue Read tool deciphers badly deformed, skewed, and poorly etched codes using optical character recognition (OCR). The pre-trained font library identifies most text without additional programming or font training for fast, easy implementation. This robust tool can be retrained to adjust to specific OCR application requirements—no vision expertise required.

|

Cognex ViDi allows technicians to train a deep learning-based model in minutes, based only on a small sample image set. Once the application is configured, ViDi delivers fast, accurate results and saves images for process control.

The VisionPro, Designer and ViDi software require that a valid Cognex Security Dongle be installed directly to PCs running the software during all phases of operation (programming, processing, training, testing, etc.). Any attempts to temporarily remove, substitute, or share a Cognex Security Dongle may cause your system to operate incorrectly, and may result in the loss of data.