BeadInspect

The BeadInspect function is used to identify positional, width, or coverage defects in a bead. The BeadInspect tool has parameters to control the bead analysis criteria and measurement rules. The initial values for these rules are set from a valid Bead data structure returned by a BeadFind function. The tool compares the bead characteristics found in the currently acquired image against the bead analysis criteria. For more information on the BeadFind function, see BeadFind.

- BeadFind and BeadInspect functions are only available on In-Sight vision systems running In-Sight firmware 5.5.0 and later. For a complete list of models and supported firmware versions, see Firmware Versions.

- BeadFind and BeadInspect functions do not support color images. If a color image is loaded, it will be automatically converted to a greyscale image.

-

For more information about how to use the BeadFind and BeadInspect functions, see Use the BeadFind and BeadInspect Functions.

BeadInspect Inputs

General Tab

Syntax: BeadInspect(Image,Bead Find,Edit Inspection Areas,Bead Edge Position Tolerance (%),Contrast Threshold,Defect Limits,Show Graphics))

| Parameter | Description |

|---|---|

|

Specifies a reference to a spreadsheet cell that contains an Image data structure; by default, this parameter references A0, the cell containing the AcquireImage Image data structure. This parameter can also reference other Image data structures, such as those returned by the Vision Tool Image functions or Coordinate Transforms Functions. |

|

| Bead Find |

Specifies a reference to a spreadsheet cell that contains a Bead data structure output by the BeadFind function. Note:

|

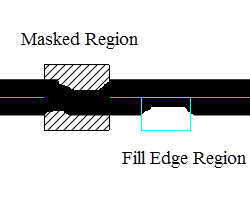

| Edit Inspection Areas | Click this button to enter Interactive Graphics Mode to edit areas that can be masked out from the inspection or allow fill edges. |

| Bead Edge Position Tolerance (%) |

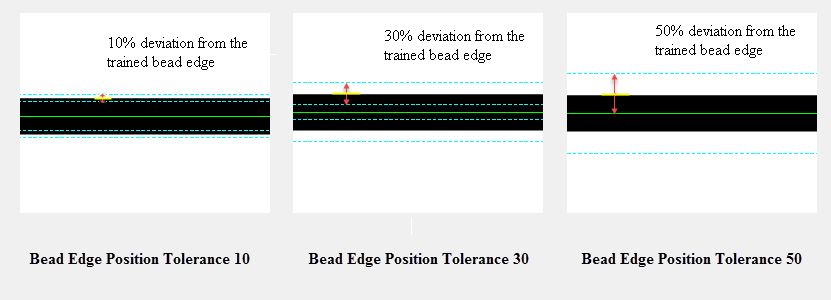

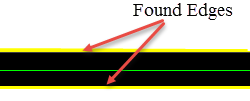

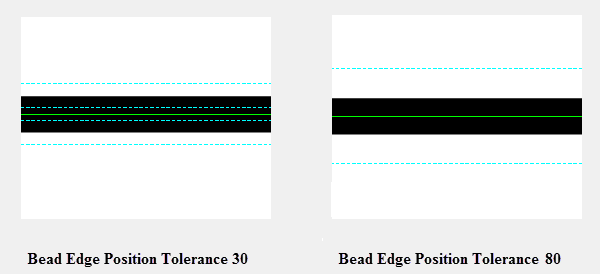

Specifies the maximum amount (1 to 200; default = 50) an edge can deviate from the trained edge position as a percentage of the average bead width at that location. Bead edges that are outside of this tolerance range will not be found. An edge must be found between the trained bead path (in green) and the Position Tolerance Boundary (in cyan). The Bead Edge Position Tolerance (%) value is measured from the trained edge position on either side of the expected edge. The average bead width is considered 100%. The trained bead path is in the middle of the bead, which is 50% deviated from the trained edge position. If the position tolerance is less than 50%, there will be two dashed lines on either side of the bead path. If the position tolerance is 50% or greater, only one single dashed line will be displayed on either side of the bead path.

|

| Contrast Threshold |

Specifies the minimum valid edge contrast value (1 to 255; default = 10). Bead edges with contrast values below this threshold will be identified as defects. |

| Defect Limits |

Specifies how defects will be defined and whether a particular type of defect should be detected. Note: When a BeadFind tool is first referenced, the default values for parameters listed below will be automatically reset to let the current bead pass the inspection with no defects found.

|

| Show Graphics |

Specifies which BeadInspect graphical overlays will be drawn on top of the image. |

Defects Tab

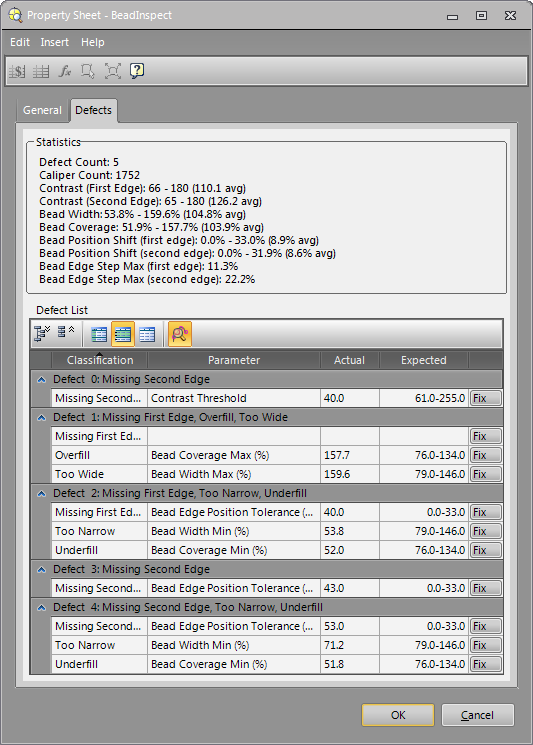

The Defects tab displays the overall results for bead inspection, and is divided into two sections: statistics and defect list.

Statistics

The statistics contain the following data and will be updated automatically after each image is loaded and/or after a change is made to the BeadInsepct function.

- Defect Count: Displays the total number of defects found in the bead.

- Caliper Count: Displays the total number of calipers in the bead path.

- Contrast (First Edge): Displays the minimum, maximum and average contrast value along the first edge of the bead.

- Contrast (Second Edge): Displays the minimum, maximum and average contrast value along the second edge of the bead.

- Bead Width: Displays the minimum, maximum and average width as a percentage of the bead.

- Bead Coverage: Displays the bead coverage as a percentage of the bead.

- Bead Position Shift (First Edge): Displays the minimum, maximum and average deviation of the first edge as a percentage of the bead width.

- Bead Position Shift (Second Edge): Displays the minimum, maximum and average deviation of the second edge as a percentage of the bead width.

- Bead Edge Step Max (First Edge): Displays the maximum step change as a percentage of the bead width along the first edge of the bead.

- Bead Edge Step Max (Second Edge): Displays the maximum step change as a percentage of the bead width along the second edge of the bead.

Defect List

The following toolbar buttons allow you to customize the display of the defect results table:

| Toolbar Button | Action |

|---|---|

|

Expand all. |

|

Collapse all. |

|

Group by defect type. |

|

Group by defect index. By default, the defect list table is grouped by defect index. |

|

No grouping. |

|

Zoom to selected defect. By default, this option is selected. The image will be automatically panned and zoomed to the location of the defect in the image. |

Defect Results Table

For each defect, the defect table will display the following:

| Parameter | Description | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Index | Displays the defect index number. | |||||||||||||||||||||||||||||

| Classification |

Displays defect type. Defect Types:

|

|||||||||||||||||||||||||||||

| Parameter | Displays the BeadInspect parameter that is associated with the defect. | |||||||||||||||||||||||||||||

| Actual | Displays actual value reported by the BeadInspect function. | |||||||||||||||||||||||||||||

| Expected | Displays the allowed value range specified by the BeadInspect parameters. | |||||||||||||||||||||||||||||

| Fix (button) |

Provides the following tuning options to remove false defects from the defect results table.

|

BeadInspect Outputs

|

Returns |

A Bead data structure containing the information about detected beads in the image, or #ERR if any of the input parameters are invalid. |

|

Results |

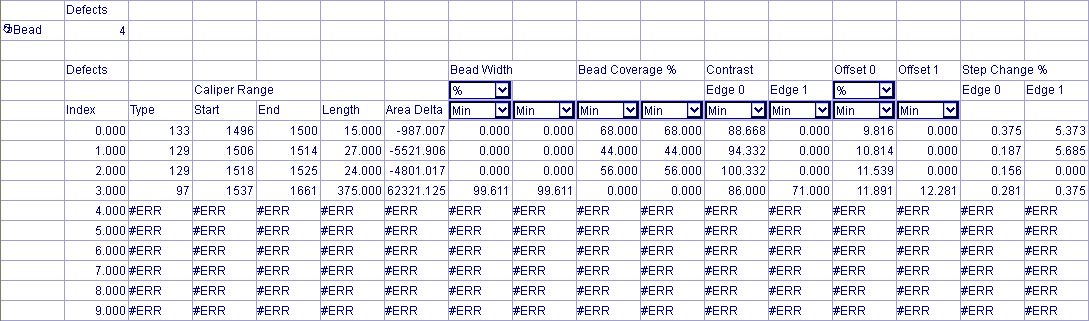

When BeadInspect is initially inserted into a cell, a results table is created in the spreadsheet. For example, this is the default BeadInspect results table:

Note:

|